A self-adjusting hot-melt welding machine is used to weld the PPR pipe and the pipe fittings, and the temperature is 260 ℃. Connect the machine to the power supply (220 V), when the green light flashes, it indicates that the welding temperature has been reached, and start to work; if the ambient temperature is lower than 5 ℃, the heating time will be extended by 50%.

Due to the light weight and flexibility of the material, all welding must be carried out on the workbench. Based on this advantage, man hours are saved.

Sometimes, some connections should be made in the wall. It should be noted that there is enough operation space at the joint location, which can be operated accurately.

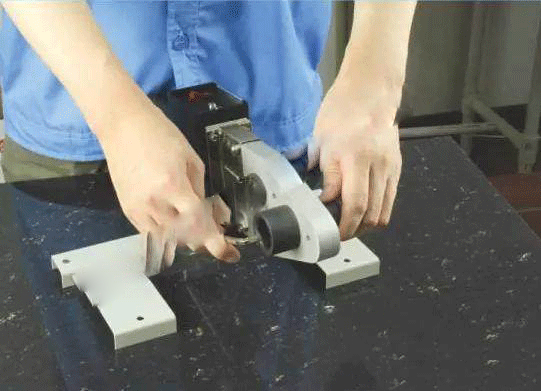

Use special scissors to cut PPR pipe, and the cut shall be smooth without burr.

Clean the welding parts of PPR pipes and pipe fittings to avoid sand, dust and other damage to the joint quality.

The heating head matched with the size of the PPR pipe to be welded is used to assemble the fuser, which is heated to 260 ℃.

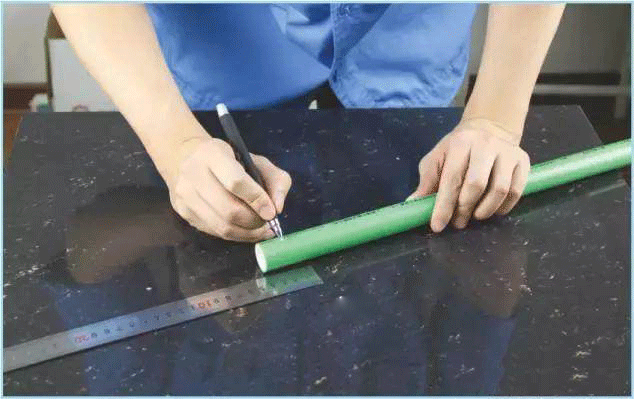

Mark the welding depth on the PPR pipe with a marking pen.

At the same time, insert the PPR pipe and pipe fittings into the welding device, and heat them according to the specified time.

After heating, push the pipe and pipe vertically and maintain for more than 5 seconds. Do not use too much force to prevent bending.